Sector

Construction

Scope

Electrical (MEPF) BIM Modeling:

Cable Trays

Electrical Closets

All Electrical Elements

Location

Israel

Deliverables

Electrical - LOD 350 BIM Model

3D DWG Files

Accuracy Report

About The Project

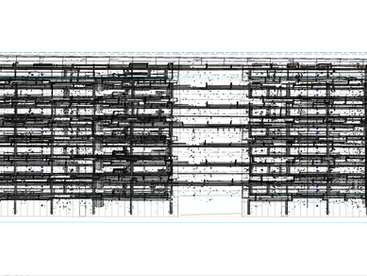

The major bank building project in Israel required the creation of a detailed as-built electrical BIM model to ensure the electrical infrastructure was accurately documented and aligned with the original design. Commissioned by an Israel-based surveying company, the project covered 1 million square feet (93K square meters), providing essential documentation for facility management and future upgrades. Using point cloud data derived from LIDAR scans, our team modeled key elements, including cable trays, electrical closets, and all electrical components. The deliverables for this project included an LOD 350 Electrical BIM model, 3D DWG files, and an accuracy report, giving the client a comprehensive overview of the building’s electrical network.

The MEPF modeling progressed in two structured phases:

1. Modeling the As-Built Conditions

- our team developed a complete LOD 350 electrical BIM model that accurately reflected the as-built conditions of the electrical infrastructure. This phase ensured all cable trays, electrical closets, and components were precisely documented.

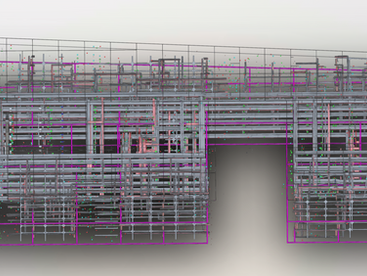

2. Electrical System Comparison – As-Built vs. Design - after completing the as-built model, our teams conducted a detailed comparison with the original design plans to identify discrepancies.

Each electrical element was classified according to the described worksets in the legend. This classification process provided the client with clear insights into deviations, allowing for quick identification and correction of inconsistencies. The as-built Electrical BIM model supports long-term facility management and system reliability.

Project Challenges & Deliverables

The electrical system modeling in this large complex introduced several challenges that demanded precision and thoroughness from our engineering and modeling teams to ensure accuracy and completeness. A significant hurdle involved cable trays distributed across three distinct height layers, complicating identification and integration into the as-built model. To address this, our teams carefully mapped each layer, ensuring that all cable trays were accurately modeled and seamlessly incorporated into the final design.

Adding to the complexity, the project encompassed thousands of electrical elements captured within the LIDAR scans. This required meticulous categorization and processing to ensure that no component was overlooked. Our engineers systematically reviewed and organized the data, guaranteeing comprehensive representation of all elements. Reflective surfaces from existing metal systems further distorted sections of the LIDAR data, presenting another layer of difficulty. Our team applied advanced filtering techniques to refine the scans, producing a clean, coherent dataset that served as the foundation for precise modeling. Limited access to certain areas also resulted in non-continuous systems and inconsistencies within the electrical network.

By analyzing the overall layout and leveraging existing data, our teams filled in missing sections, ensuring the delivery of a fully connected and operational electrical model. This thorough and structured approach allowed us to overcome the project's challenges, providing a highly accurate and reliable electrical systems BIM model that supports ongoing facility management and operational efficiency.

The electrical system modeling in this large complex introduced several challenges that demanded precision and thoroughness from our engineering and modeling teams to ensure accuracy and completeness. A significant hurdle involved cable trays distributed across three distinct height layers, complicating identification and integration into the as-built model. To address this, our teams carefully mapped each layer, ensuring that all cable trays were accurately modeled and seamlessly incorporated into the final design.

Adding to the complexity, the project encompassed thousands of electrical elements captured within the LIDAR scans. This required meticulous categorization and processing to ensure that no component was overlooked. Our engineers systematically reviewed and organized the data, guaranteeing comprehensive representation of all elements. Reflective surfaces from existing metal systems further distorted sections of the LIDAR data, presenting another layer of difficulty. Our team applied advanced filtering techniques to refine the scans, producing a clean, coherent dataset that served as the foundation for precise modeling. Limited access to certain areas also resulted in non-continuous systems and inconsistencies within the electrical network.

By analyzing the overall layout and leveraging existing data, our teams filled in missing sections, ensuring the delivery of a fully connected and operational electrical model. This thorough and structured approach allowed us to overcome the project's challenges, providing a highly accurate and reliable electrical systems BIM model that supports ongoing facility management and operational efficiency.