Sector

Construction

Scope

Fire MEPF Modeling

Pump & Fire Risers Rooms

All Fire Protection Electrical Elements

Piping

Sprinklers

Location

USA

Deliverables

Fire Protection & Plumbing - LOD 350 BIM Model

3D DWG Files

Accuracy Report

About The Project

The commercial office facility project in USA required the development of a detailed as-built Fire Protection BIM model including the plumbing setup to ensure the building’s fire suppression systems were accurately documented and aligned with original design plans. Commissioned by a US-based surveying company, the project spanned 277K square feet (25.7K square meters) and aimed to provide essential documentation for facility management and compliance.

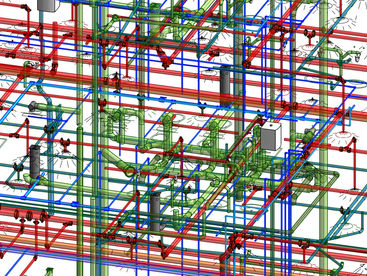

Fire protection systems are critical to safeguarding lives and assets in large commercial facilities, forming an essential part of MEPF infrastructure. This project focused on ensuring the accuracy and reliability of the fire protection network, covering all critical components. Using point cloud data derived from LIDAR scans supplied by the client, our team modeled essential fire protection elements, including piping, pump rooms, fire riser rooms, sprinklers, and electrical components such as alarms and activation buttons. The deliverables for this project consisted of an LOD 350 Fire Protection BIM model, 3D DWG files, and an accuracy report, providing our client with comprehensive tools to manage and maintain the fire suppression systems.

Our work progressed in two structured phases:

1. Modeling the as-built conditions - our team developed a complete LOD 350 BIM model that accurately incorporated the building layout and fire protection systems. This phase captured the as-built conditions, ensuring a detailed and reliable representation of the fire suppression infrastructure.

2. Fire Protection System Comparison – As-Built vs. Design

Upon completion of the as-built model, our team conducted a thorough comparison with the original design plans to identify discrepancies.

Each fire protection element was classified into the described worksets in the legend. This classification process provided clear insights into deviations from the original design, enabling the client to address inconsistencies effectively. The as-built Fire Protection BIM model supports long-term facility maintenance, ensuring compliance with fire safety regulations and efficient system management.

Project Challenges & Deliverables

The fire protection modeling phase posed several challenges, requiring our engineering and modeling teams to ensure both accuracy and completeness throughout the process. One of the primary issues involved missing data caused by thin fire pipes concealed above structural elements. To overcome this, our team carefully analyzed the visible data and applied their expertise to reconstruct the missing sections, ensuring the system was fully connected and operational.

Additionally, the modeling of water riser and pump rooms demanded extensive model-in-place work due to the complexity of the machinery and piping layouts. Our engineers meticulously crafted these components by hand, guaranteeing precision and capturing even the smallest details. Another challenge arose from reflective scans caused by metal systems above the ceiling, which distorted the LIDAR data. To address this, our team implemented advanced filtering techniques to refine the scans, resulting in a clean dataset that allowed for accurate modeling.

Limited access to certain areas further complicated the process, leading to non-continuous systems and inconsistencies. To resolve this, our engineers conducted a thorough analysis of the layout and filled in the missing sections, ultimately delivering a continuous and fully integrated model. By tackling each of these challenges head-on, our teams successfully produced a reliable Fire Protection BIM model that supports long-term system safety, performance, and ongoing maintenance.

The fire protection modeling phase posed several challenges, requiring our engineering and modeling teams to ensure both accuracy and completeness throughout the process. One of the primary issues involved missing data caused by thin fire pipes concealed above structural elements. To overcome this, our team carefully analyzed the visible data and applied their expertise to reconstruct the missing sections, ensuring the system was fully connected and operational.

Additionally, the modeling of water riser and pump rooms demanded extensive model-in-place work due to the complexity of the machinery and piping layouts. Our engineers meticulously crafted these components by hand, guaranteeing precision and capturing even the smallest details. Another challenge arose from reflective scans caused by metal systems above the ceiling, which distorted the LIDAR data. To address this, our team implemented advanced filtering techniques to refine the scans, resulting in a clean dataset that allowed for accurate modeling.

Limited access to certain areas further complicated the process, leading to non-continuous systems and inconsistencies. To resolve this, our engineers conducted a thorough analysis of the layout and filled in the missing sections, ultimately delivering a continuous and fully integrated model. By tackling each of these challenges head-on, our teams successfully produced a reliable Fire Protection BIM model that supports long-term system safety, performance, and ongoing maintenance.