Sector

Construction

Scope

Fire MEPF BIM Modeling

Pump & Fire Risers Rooms

Fire Protection Electrical Elements

Piping

Sprinklers

Location

Israel

Deliverables

Fire Protection & Plumbing - LOD 350 BIM Model

3D DWG Files

Accuracy Report

About The Project

The Apple Office Building project in Israel required the development of a precise as-built BIM model for the fire protection systems including the plumbing setup to ensure the facility aligned with the original design plans. Commissioned by an Israeli-based construction company, the project aimed to verify the accuracy of the fire protection infrastructure, providing critical documentation for facility management and safety compliance.

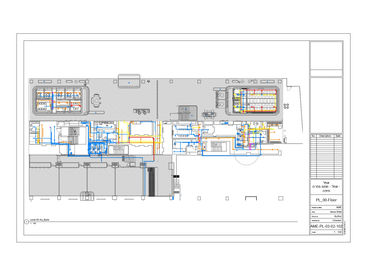

Spanning 250K SF (23K square meters), the project involved full architectural BIM modeling with a focus on fire protection. Using LIDAR scan data provided by the client, we modeled key components, including piping, pump rooms, fire riser rooms, sprinklers, and fire protection electrical elements such as alarms and activation buttons. The deliverables included a LOD 350 as-built BIM model, 3D DWG files, and an accuracy report, providing Apple with essential resources for ongoing system management and maintenance.

Fire protection systems are essential to safeguarding lives and assets, forming a core part of MEP designs in commercial buildings. This project ensured Apple’s facility met strict safety standards by delivering a comprehensive and accurate BIM model of the fire suppression and alarm systems.

Our work was divided into two phases:

1. Modeling the as-built conditions from scratch – we developed a comprehensive LOD 350 as-built BIM model that accurately incorporates architectural layouts and all existing fire protection components.

2. Fire protection system detailed comparison – As-Built vs. Design - after completing the as-built model, we conducted an in-depth comparison of the fire protection system against the design plans provided by the client.

Each fire protection element was evaluated and classified based on its alignment and accuracy relative to the design, according to the described worksets in the legend. This detailed classification provided our client with clear insights into discrepancies, ensuring deviations from the original design were quickly identified and addressed. The accurate as-built BIM model supports efficient facility management, ongoing maintenance, and long-term safety compliance.

Project Challenges & Deliverables

The Apple project required advanced problem-solving to produce an accurate as-built fire protection BIM model, relying on our engineering expertise to ensure system precision and continuity. A key challenge was the concealment of thin fire pipes above structural elements, complicating detection. Using our extensive MEPF experience, we analyzed visible sections and extrapolated missing routes, ensuring a fully connected fire protection network. In the pump and riser rooms, dense machinery and incomplete scans required model-in-place techniques. Our team manually reconstructed layouts based on system logic, delivering precise as-built representations.

Reflective LIDAR scans caused data fragmentation due to interference from metal structures. We applied advanced filtering to rebuild a coherent point cloud, forming a reliable base for modeling. Restricted access to certain areas resulted in discontinuities in the fire protection layout. Our engineers analyzed the design and completed missing sections, creating a continuous and operational system. By addressing these challenges, we delivered a precise and reliable fire protection BIM model, equipping Apple’s facility management team with essential tools for maintenance, compliance, and long-term system integrity.

The Apple project required advanced problem-solving to produce an accurate as-built fire protection BIM model, relying on our engineering expertise to ensure system precision and continuity. A key challenge was the concealment of thin fire pipes above structural elements, complicating detection. Using our extensive MEPF experience, we analyzed visible sections and extrapolated missing routes, ensuring a fully connected fire protection network. In the pump and riser rooms, dense machinery and incomplete scans required model-in-place techniques. Our team manually reconstructed layouts based on system logic, delivering precise as-built representations.

Reflective LIDAR scans caused data fragmentation due to interference from metal structures. We applied advanced filtering to rebuild a coherent point cloud, forming a reliable base for modeling. Restricted access to certain areas resulted in discontinuities in the fire protection layout. Our engineers analyzed the design and completed missing sections, creating a continuous and operational system. By addressing these challenges, we delivered a precise and reliable fire protection BIM model, equipping Apple’s facility management team with essential tools for maintenance, compliance, and long-term system integrity.